ADB HOIST RINGS MFG 33105起重吊环2500LBS americandrillbushing代理销售美国工业品

ADB HOIST RINGS MFG 33105起重吊环2500LBS americandrillbushing代理销售美国工业品

ADB ®是起重吊环和安全起重设备的开创者和行业领先制造商。我们的设备用于制造和建筑的许多领域。产品应用领域包括航空航天与国防、冲压与注塑、发电;核能、水力、风能和太阳能,包括隧道掘进、预制板、倾斜和管道安装、道路建设等在内的建筑。我们的质量保证计划确保我们所有的产品都按照 ASTM 1444 进行磁粉检测。

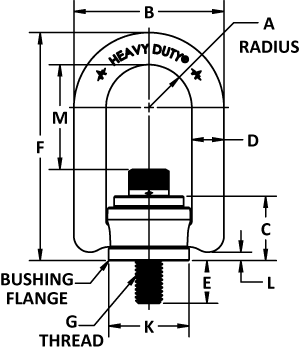

| Part No. |

Rated Load (lbs) |

A | B | C | D | E +/- .12 |

F | G | K | L | M | TL (ft-lbs) |

Weight (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 33112 | 550 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 1/4-20 | 1.25 | 0.15 | 1.57 | 5 | .50 |

| 33212 | 800 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 5/16-18 | 1.25 | 0.15 | 1.51 | 7 | .52 |

| 33213 | 800 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 5/16-24 | 1.25 | 0.15 | 1.51 | 7 | .52 |

| 33214 | 800 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 5/16-18 | 1.25 | 0.15 | 1.51 | 7 | .54 |

| 33312 | 1000 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 3/8-16 | 1.25 | 0.15 | 1.45 | 12 | .56 |

| 33313 | 1000 | .65 | 2.29 | .96 | .44 | .56 | 3.23 | 3/8-24 | 1.25 | 0.15 | 1.45 | 12 | .56 |

| 33314 | 1000 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 3/8-16 | 1.25 | 0.15 | 1.45 | 12 | .58 |

| 33316 | 2250 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 1/2-13 | 1.25 | 0.15 | 1.45 | 26 | .60 |

| 33317 | 2250 | .65 | 2.29 | .96 | .44 | 1.06 | 3.23 | 1/2-20 | 1.25 | 0.15 | 1.45 | 26 | .60 |

| 33512 | 2500 | 1.00 | 3.50 | 1.50 | .75 | .75 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.71 |

| •33513 | 2500 | 1.00 | 3.50 | 1.50 | .75 | .75 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.04 |

| 33515 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.72 |

| •33505 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.05 |

| 33516 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 5.31 | 1/2-13 | 1.89 | 0.17 | 2.56 | 28 | 1.82 |

| •33517 | 2500 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 6.87 | 1/2-13 | 1.89 | 0.17 | 4.12 | 28 | 2.15 |

| 33612 | 4000 | 1.00 | 3.50 | 1.50 | .75 | .75 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.76 |

| •33613 | 4000 | 1.00 | 3.50 | 1.50 | .75 | .75 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.09 |

| 33614 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.78 |

| •33604 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.11 |

| 33615 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 5.31 | 5/8-11 | 1.89 | 0.17 | 2.44 | 60 | 1.88 |

| •33616 | 4000 | 1.00 | 3.50 | 1.50 | .75 | 1.25 | 6.87 | 5/8-11 | 1.89 | 0.17 | 4 | 60 | 2.21 |

| 33714 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 5.31 | 3/4-10 | 1.89 | 0.17 | 2.31 | 100 | 1.89 |

| •33715 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.00 | 6.87 | 3/4-10 | 1.89 | 0.17 | 3.87 | 100 | 2.22 |

| 33716 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.50 | 5.31 | 3/4-10 | 1.89 | 0.17 | 2.31 | 100 | 2.02 |

| •33717 | 5000 | 1.00 | 3.50 | 1.50 | .75 | 1.50 | 6.87 | 3/4-10 | 1.89 | 0.17 | 3.87 | 100 | 2.35 |

| 33110 | 6300 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.23 |

| 33108 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.20 |

| •33168 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.93 |

| 33102 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .1.20 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.23 |

| •33162 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | .1.20 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.96 |

| 33103 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 3/4-10 | 2.81 | 0.18 | 3.57 | 100 | 7.25 |

| •33163 | 7000^ | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 3/4-10 | 2.81 | 0.18 | 5.20 | 100 | 7.98 |

| 33104 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33164 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | .95 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.95 | 160 | 8.06 |

| 33101 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33161 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.82 | 160 | 8.06 |

| 33109 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 7/8-9 | 2.81 | 0.18 | 3.32 | 160 | 7.33 |

| •33169 | 8000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 7/8-9 | 2.81 | 0.18 | 4.82 | 160 | 8.06 |

| 33105 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.57 |

| •33165 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.45 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.30 |

| 33106 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.63 |

| •33166 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 1.20 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.36 |

| 33107 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 2.20 | 7.37 | 1″-8 | 2.81 | 0.18 | 3.20 | 230 | 7.81 |

| •33167 | 10000 | 1.50 | 5.10 | 2.05 | 1.00 | 2.20 | 9.00 | 1″-8 | 2.81 | 0.18 | 4.82 | 230 | 8.54 |

| 33402 | 15000 | 2.00 | 6.75 | 2.89 | 1.25 | 1.88 | 9.22 | 1 1/4″-7 | 3.75 | 0.40 | 3.76 | 470 | 15.7 |

| 33401 | 15000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 1/4″-7 | 3.75 | 0.40 | 3.76 | 470 | 16.0 |

| 33420 | 20000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 3/8″-6 | 3.75 | 0.40 | 3.64 | 670 | 17.2 |

| 33424 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.63 | 9.22 | 1 1/2″-6 | 3.75 | 0.40 | 3.51 | 800 | 18.1 |

| †33436 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.27 | 1 3/4″-5 | 3.75 | 0.40 | 3.51 | 800 | 20.2 |

| †33438 | 24000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.27 | 1 3/4″-8 | 3.75 | 0.40 | 3.51 | 800 | 20.2 |

| †33427 | 30000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.22 | 2″-4 1/2 | 3.75 | 0.40 | 3.51 | 1100 | 22.9 |

| †33432 | 30000 | 2.00 | 6.75 | 2.89 | 1.25 | 2.96 | 9.22 | 2″-8 | 3.75 | 0.40 | 3.51 | 1100 | 22.9 |

| NEW ITEMS | |||||||||||||

| 33501 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2-1/2-8 | 5.16 | 0.58 | 4.9 | 2400 | 50.4 |

| 33503 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2-1/2-4 | 5.16 | 0.58 | 4.9 | 2400 | 50.4 |

| 33590 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2-1/2-8 | 5.16 | 0.58 | 4.47 | 56 | 57.2 |

| 33592 | 55000 | 2.75 | 9.25 | 3.96 | 1.75 | 4 | 12.86 | 2-1/2-4 | 5.16 | 0.58 | 4.47 | 56 | 57.2 |

Material: Forged and machined high strength alloy steel

Design Factor: Minimum Design Factor = 5:1, Magnetic Particle Inspected Per ASTM E1444, Hoist Rings retain the same rated load from 0 to 90 degrees from the bolt axis

Range of Movement: Swivel 360°, Pivot 180° Under Load

Specifications: Meets Military Specification No. MIL-STD 209, Meets ANSI/ASME B30.26

Finish: Black Oxide Finish for corrosion resistance, * Also available in a wide